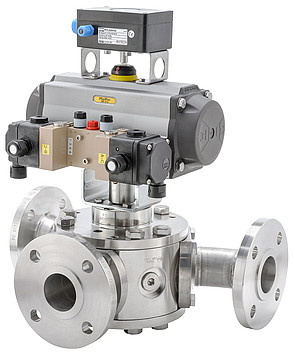

BR 29a - pneumatic - DIN

Piggable valve

VALVE STYLE

Piggable valve

USAGE

- Low-pressure service

- Mixing or diverting service

- On/off service

VERSION

DIN

MEDIUM TEMPERATURE

-10

to 200 °C /

14

to

392 °F

SUPPLY

Pneumatic

VALVE SIZE

DN 50

to

DN 200

PRESSURE RATING

PN 25

to

PN 40

LINING

without

Special features

- Consisting of ball valve and actuator

- Multi-way Diverting Valve at 45° / 60° or 90°

- Inside diameter of pipe, according to DIN 2430

- Large flexion radius (4D)

- Complex mounted ball

- Corrosion-resistant materials to withstand corrosive process media

- DIN ISO 5211 interface as standard

- PTFE V-ring packing loaded by disk springs

- TA-Luft

- Blow-out-proof shaft

- Anti-static version with conductive shaft bearing

- Leakage requirements according to DIN EN 12266 or API 598

- » General information about pigging systems

- For pipes and valves acc. to DIN2430

- High cleaning performance without any additional rinsing process

- Long service life (depending on media)

- Resistant to chemicals even with corrosive media

- Two distinctive sealing lips and a formed middle part enable it to run without any problems in bends

- Bi-directional operation mode, i.e. the pig is symmetric, therefore can be used in both directions

- A magnet in core of the pig allows use in automated systems

- Pigs maintain a constant and even run inside bends and valves

- Sealing lip diameter approx. 4 % larger than the pipe diameter for a much higher scrape performance

Accessories

- Manual gearbox

- Locking facility

- Limit switch

- Solenoid valves

- Positioner

- Air pressure supply regulator/filter

- Changeable lips

Options

- Shaft extension

- Interchangeable pneumatic, or electric actuator (120°)

- Minimised cavity, with PTFE-strips

- Various designs

- With pigging signal strips in automatic systems, for mounting magnetic-inductive pigging sensors

- With an incremental controlled coupling as a 3/3-way diverting valve

- Seat rings in PTFE-compounds

- Sealing in graphite

- Heating jacket (body only)

- Larger nominal diameter on request

- Pigs with solid elastomer body

- Pigs in various special materials and designs

- Pigs screwed together in several parts

- Pigs made from highly resistant materials

- Magnetic pigs with powder filling without risk of magnet leakage

- Pigs in high temperature design

- Food approval for pigs

BR 29a - pneumatic - DIN can be combinated with the following actuations:

Special features:

- Single-acting and double-acting piston actuator

- Suitable for strict requirements in chemical plants

- Opening angle 90°

- Signal pressures up to 10 bar

- Torques from 5 to 11674 Nm

- Temperatures from –40 to +80 °C

- End positions adjustable within wide range (+5°/–15°)

- Diagonal or parallel square drive position

- Position indicator adjustable in steps of 45°

- Encapsulated spring assemblies

- Power transmission without clearance thanks to involute gearing

- Direction of rotation reversible without requiring additional parts

- Surface treatment tested by Kesternich sulfur dioxide corrosion test and salt spray test

- Centering ring milled into the housing

- Standardized attachment of valve accessories according to VDI/VDE 3845 or NAMUR

- Simple attachment according to DIN EN ISO 5211

- Blow-out-proof travel stop screws

- Fast stroking speeds as standard

Special features:

- Single-acting and double-acting piston actuator

- Suitable for strict requirements in chemical plants

- Opening angle 90°

- Signal pressures up to 10 bar

- Torques from 18 to 1702 Nm

- Temperatures from –40 to +80 °C

- End positions adjustable within wide range (+5°/–15°)

- Additional pneumatic input at the top shaft end

- Diagonal or parallel square drive position

- Position indicator adjustable in steps of 45°

- Encapsulated spring assemblies

- Backlash-free force transmission thanks to involute gearing

- Direction of rotation reversible without requiring additional parts

- Surface treatment tested by Kesternich sulfur dioxide corrosion test and salt spray test

- Centering ring milled into the housing

- Standardized attachment of valve accessories according to VDI/VDE 3845 / NAMUR and VDI/VDE 3847

- Simple attachment according to DIN EN ISO 5211

- Blow-out-proof travel stop screws

- Fast stroking speeds as standard

- Integrated Automation acc. to VDI/VDE 3847

Information

Support

Certificates

Only up-to-date documents are shown in the product selector. Check the documentation site for a list of all documents available.

Pin items on your list and contact us if you have any product-related questions.

Back to product selector